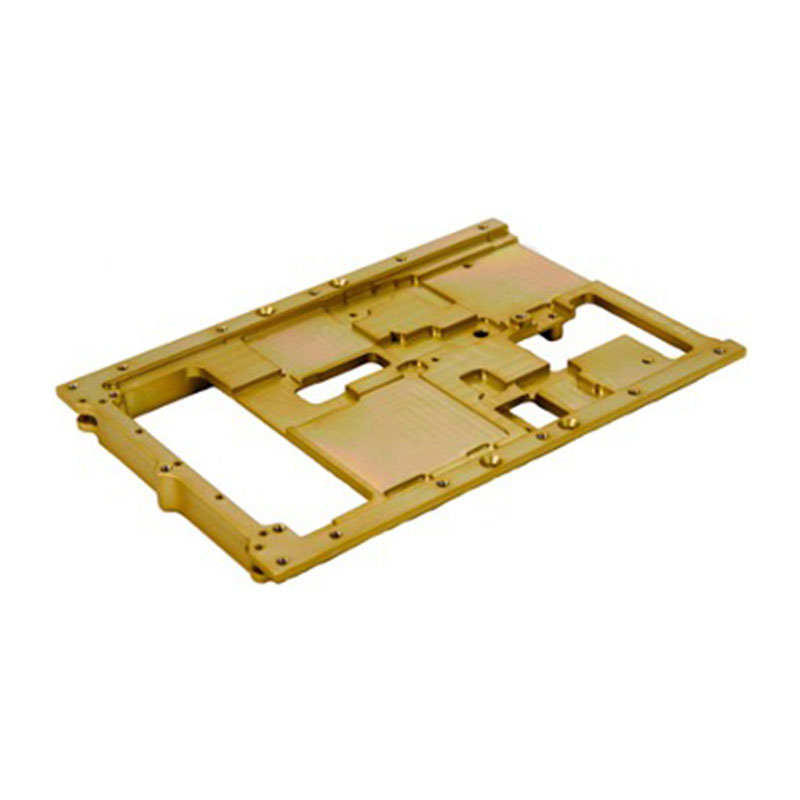

Wakefield Thermal Rugged and Defense Products, located in Raleigh, North Carolina, has extensive experience in manufacturing milled aluminum heat frames for use with electronics designed to meet or exceed rugged specification requirements. Heat frames are CNC precision-machined out of solid aluminum (or copper) and precisely match the topography or skyline of an electronic printed circuit board being ruggedized. When combined with thermal-interface material or “gap pads,” conduction-cooled heat frames increase a board’s operating temperature range, as well as its resistance to shock and vibration. When integrated with wedgelocks and ejectors, this product allows VME, cPCI and other boards to fit within conduction cooled chassis slot dimensions with zero insertion force. Heat frames can be designed for compliance with IEEE 1101.2, VITA 30.1, and VITA 48 (both 0.8” and 1.0” slot pitch), and can also accommodate mezzanine cards as needed.

Available plating options include Chromate, Black Anodize, and Electroless Nickel.

Designs can integrate Front or Rear I/O and can also include Top and Bottom Covers for compliance with Two-Level Maintenance.

US Dollars

US Dollars