End-to-End Services

Wakefield Thermal is able to control cost, quality, and lead times.

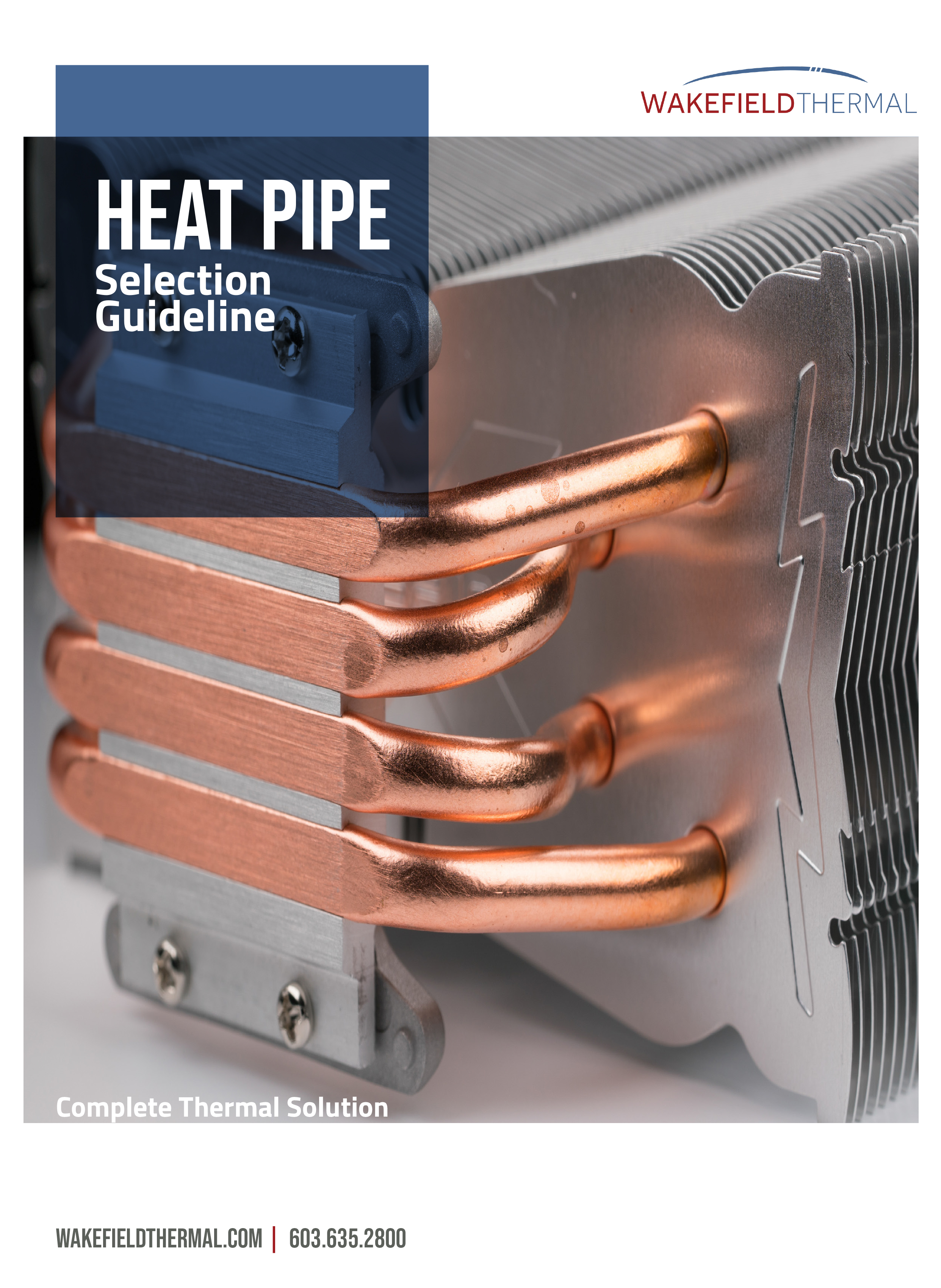

Thermal Challenge

Smaller footprints and higher power densities in consumer & military electronics has become a universal dilemma with emerging technologies. Wakefield Thermal has been facing these challenges dating back to the first mainframe computing was developed. As technology evolves, the thermal challenges increase, that is where Wakefield Thermal solves the issue at hand.

Validation

Typically, thermal requirements are the last to be considered in the design process. This may leave a design engineer in a tough position. Wakefield Thermal strives in collaboration with its customers engineers to overcome these inherited challenges. Helping you get across the finish line of design is our top priority.

Supply Chain

An end-to-end global supply chain with sales, engineering, manufacturing, and delivery being tightly-coupled means Wakefield Thermal customers have continued global support from initial design through final delivery. We want you to always know we have your back even when the overwhelming thermal challenge presents itself on next generation product.

Design Assistance & Engineering Resources

Wakefield Thermal has an experienced team of applications engineers that can assist you with solving your thermal problems. Our experienced engineers have worked in the industry for years, working on problems from board level cooling to complex liquid cooled solutions. The engineering team will help you work a problem from initial concept through to production, which includes designing assistance and access to engineering resources. In the initial concept phase, we can evaluate various technologies (extrusion, bonded, zipper, etc.) to ensure the engineered solution is cost effective and manufacturable at prototype or production quantities.

Our Applications Engineers have access to CFD simulation tools as well as proprietary design software to quickly evaluate thermal performance. Once the application is ready, the Applications Engineers can generate a quotable drawing package for a final manufacturing review. In addition to the thermal portion of the problem, the engineers can assist you with TIM selection and mechanical attachment methods, such as clamps, clips, pushpins, or wireclips.

Resources and References

US Dollars

US Dollars